| Телефон | +7 (800) 222-79-20 |

| Адрес | Russia, Ryazan, pos. Murmino, Verhne-Sadovaya street, 1, 390528 |

| mb@pak-rz.ru |

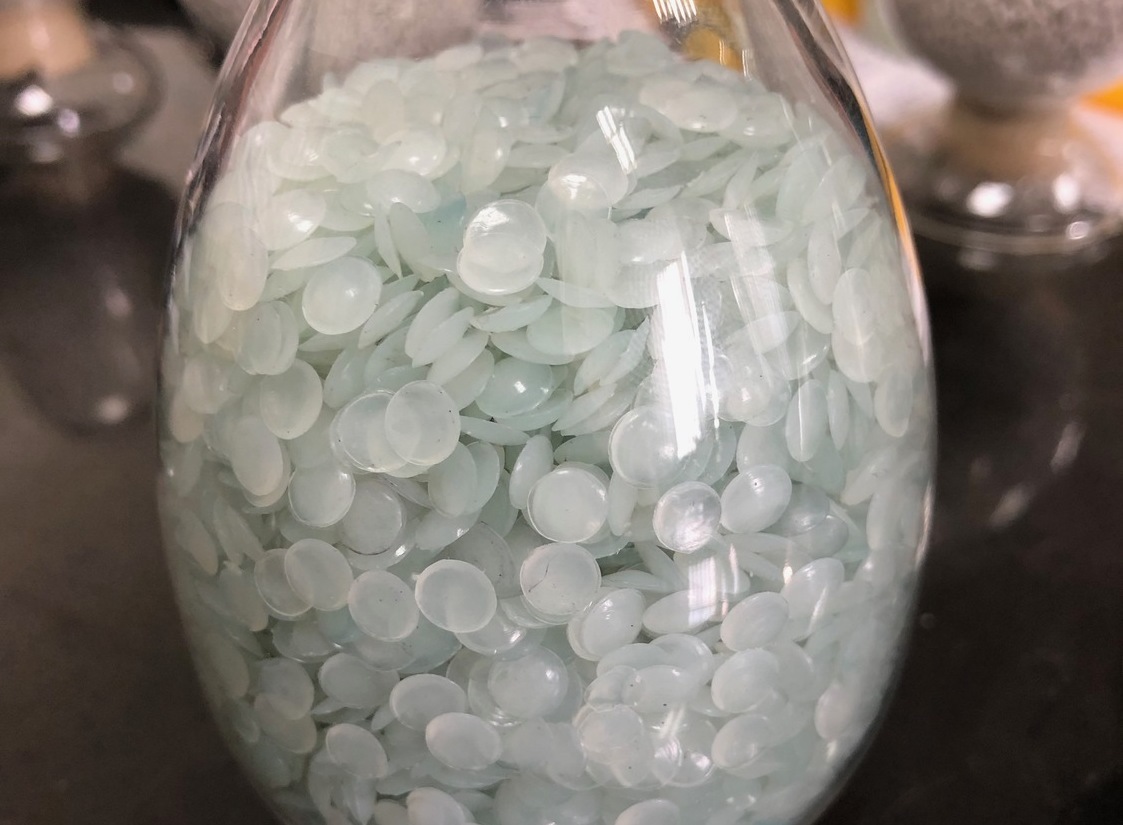

Sliding Additive (Slip additive)

Slip E and Slip O

Sliding additives (slip additive) are the material whose main task is to reduce the friction coefficient of films used for the packaging of bulk and liquid substances.

The technological additive is effectively used in the field of thin-walled casting, which makes it possible to improve the spillness indicators and enhance the brilliance of finished products, as well as facilitate its removal from the form.

Films made of high pressure polyethylene and low pressure polyethylene are distinguished by a tendency to stick and friction, which reduces the level of strength, and accordingly the quality of finished products. This leads to an increase in the cost of finished material, the difficulties of winding film on the roll, there are difficulties with welding products and printing.

Using the slick of additives allows you to successfully solve these production and technological problems. To solve various tasks, two types of sliding additives are applied: Slip E and Slip O.

Slip O (Oleomid Additive)

The sliding additive SLIP O is an active substance such as an oleic acid amide or oleamide.

Oleamide allows you to maximize the level of friction and limits the possibility of sticking polymer products.

The main difference between the active substance from Erukovda is that it migrates faster on the surface of the film and begins to act immediately after the manufacturer of the film. The maximum effect of application is achieved after 24 hours.

Slip E sliding additive (Erouvoid additive)

The basis of the polymer sliding supplement Slip E lies amide an erukic acid or erukid.

Erukovd gives the opportunity to achieve the maximum sliding effect, and eliminate the possibility of friction. The molecular weight of Erukovda is much larger than the oleamide, and therefore the substance begins to act 5 hours after the manufacture of products. The full impact of the additive begins to appear after 3-4 days after the production of products.

This feature determines the need to use this concentrate for products to be seal or welding is applied immediately after exiting the conveyor. Due to the longer migration, slip additives to the surface of the film, the print fixation is improved and the reliability of the welding seam increases.

Advantages of using slip additives

The introduction of polymer additives makes it possible to experience a number of advantages:

- For the production of sliding additives, high quality raw materials are used, which ensures the required functional properties;

- Improve the appearance of products and its technological characteristics;

- Help reduce adhesion and friction;

- Do not affect the mechanical and optical properties of polymers;

- Multifunctionality of additives allows them to be used with different types of polymers.

Polymer additives produced by our company have quality certificates and certificates of state registration.

Recommendations for entering additives

The practical experience of using and laboratory tests of Supplements Slip E and Slip O allowed us to formulate recommendations for their input. Enter the additive is recommended as a percentage ratio of 0.5-1.5% by weight of the polymer.

The exact content of the additive is determined by the following factors:

- the desired level of friction;

- film thickness;

- chemical and technological properties of material products;

- the need to apply print or apply welding technologies.

If you have questions about entering additives, you can set them to our technologists when placing an order.