| Телефон | +7 (800) 222-79-20 |

| Адрес | Russia, Ryazan, pos. Murmino, Verhne-Sadovaya street, 1, 390528 |

| mb@pak-rz.ru |

Fillers

Fillers for polymers

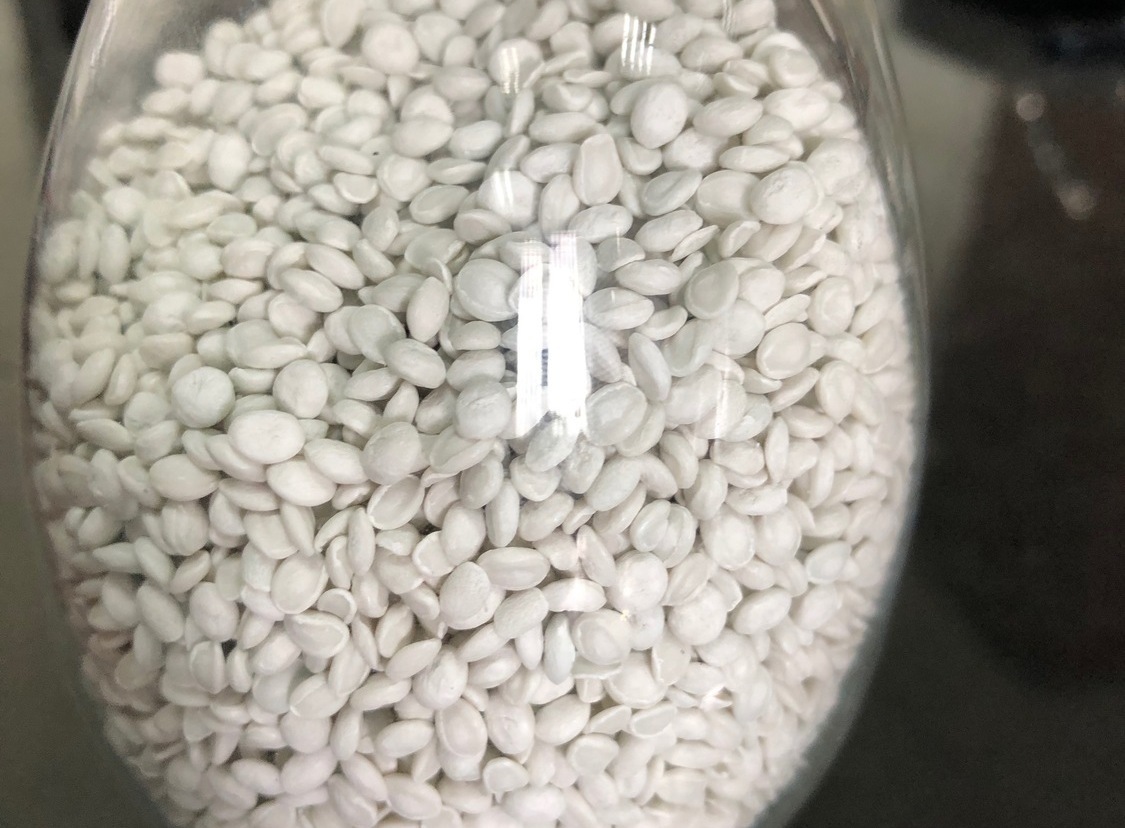

CaCo3 Filler - is a masterbatch used in order to modify the properties of polymeric raw materials and an increase in production profitability.

The chalk superconcentrate has a complex chemical composition, which includes calcium carbonate, polymer base based on linear polyethylene, as well as a number of additives.

The chalk compound is produced in a granular form, which makes it possible to ensure uniformly mixing of the polymer and additives and homogeneity, which plays an important role in the processing process.

The versatility of the additive allows it to be used in industrial and chemical production. Depending on the technological characteristics, the chalk additive is used in the process of manufacturing containers for various types of products, bags and packages, threads, films, toys, disposable dishes and casting of pipes, as well as for the production of blowing products.

CaCo3 filler- compound (filler for polymers), which can consist of calcium carbonate or talc, polyethylene or propylene, as well as a number of special processing additives. All chalk concentrates (additives) We produce only with the use of high-quality, micrometkodisser marble calcium carbonate and linear polyethylene. Our additives are excellent perfectly dispersed with different polymers of Na Wounts PND, PVD, PP. Also, our additives have low abrasiveness. Our chalk additives can be used both for the production of painted products in the mass and for transparent products, since we use only high-quality components they do not give strong stamps in products. Cretaceous additives can be used to produce pipes, cables, polymer films, in blown molding, fiber production. Daim Ltd. produces additives minor blank and talcopillated.

Properties of fillers

Thalk compounds comprehensively affect the polymeric raw materials:

1. CaCO3 in the composition of the additive increases the strength, rigidity and density of the product, which is especially relevant in the manufacture of pipes and various containers;

2. Increase the heat resistance of the material and reduce susceptibility to temperature differences;

3. Increase the stability of products to negative mechanical effects;

4. Make it possible to reduce the cost of production by reducing the raw materials of dyes, sliding and anti-Block additives;

5. Reducing shrinkage;

6. Low abrasiveness;

7. No need for coronary processing;

8. Improving the tactile properties of finished products;

9. Improving fixation of flexographic paint.

DIME manufactures several types of chalk concentrates, which are characterized by technological and chemical properties, which allows you to choose a compound that meets the production needs.

CaCo3 Filler Cadi IV

| № | Specifications | |||

| 1 | Content CaCo3 | 80% | ||

| 2 | LDPE / LLDPE content | 16% | ||

| 3 | Elastomer content | 4% | ||

| 4 | Whiteness | 86±3% | ||

| 5 | Particle size | 1 micron | ||

| 6 | Applicability to | LDPE/HDPE/PP | ||

It is performed on the basis of high-quality, fine natural chalk and linear polyethylene. The percentage of administration can be in the range from 5% and reach 50%, depending on the specific product and processing conditions.

Cretaceous additives for polymers. Advantages of use.

The introduction of chalk concentrate for production allows the following advantages:

1. Reduce the cost of raw materials;

2. Reducing the cost of maintenance and repair of equipment. The granular shape of the chalk additive does not allow filters to be clogged in the processing process;

3. Reducing costs for expensive dyes, ensuring uniform painting of finished products and its attractive appearance;

4. Increase the quality and strength of products;

5. The ability to dosing the chalk additive both by weight and by the volume of raw materials;

6. Improving consumer properties of products and a decrease in the number of defective products;

7. Improving the ecology of production;

8. Due to the use of chalk, the separation of the polypropylene thread is excluded, the product's mattability improves;

9. Calculate warning, shrinkage of finished products;

10. The high heat resistance of the masterbatches allows you to use it as an antipyrin, thereby increasing the temperature threshold of thermal deformation of products.

Production of chalk additives in the company "DIME" is carried out in accordance with the advanced technologies of Chinese fillers factories. This makes it possible to produce a quality product that meets the production requirements of customers.

Buy a chalk additive, possibly placing an order by phone indicated on the site, or leaving an application by email. Managers of the company are ready to advise on the range of assortment and help place an order!

CaCo3 Filler Cadi V

| № | Specifications | |||

| 1 | Content CaCo3 | 80% | ||

| 2 | LDPE / LLDPE content | 16% | ||

| 3 | Elastomer content | 4% | ||

| 4 | Whiteness | 94±3% | ||

| 5 | Particle size | 0,8-1 мкм | ||

| 6 | Applicability to | LDPE/HDPE/PP | ||

It is performed on the basis of high-quality, fine natural chalk and linear polyethylene. The percentage of administration can be in the range from 5% and reach 50%, depending on the specific product and processing conditions.

Filler Cadi VIII

| № | Specifications | |||

| 1 | Content CaCo3 | 80% | ||

| 2 | LDPE / LLDPE content | 16% | ||

| 3 | Elastomer content | 4% | ||

| 4 | Whiteness | 90±3% | ||

| 5 | Particle size | 0,8-1 мкм | ||

| 6 | Applicability to | LDPE/HDPE/PP | ||

It is performed on the basis of high-quality, fine natural chalk and linear polyethylene. The percentage of administration can be in the range from 5% and reach 50%, depending on the specific product and processing conditions.

Company DIME LTD

| Телефон | +7 (800) 222-79-20 |

| Адрес | Russia, Ryazan, pos. Murmino, Verhne-Sadovaya street, 1, 390528 |

| mb@pak-rz.ru |