| Телефон | +7 (800) 222-79-20 |

| Адрес | Russia, Ryazan, pos. Murmino, Verhne-Sadovaya street, 1, 390528 |

| mb@pak-rz.ru |

Modifying additives

Additives to change and improve the properties of polymers.

Slip E and Slip O

The Slip additive is used in the production of packaging films from polyethylene, it is indispensable in a thin-walled casting in order to improve spillage indicators.

Its main task is to provide a slide of the layers of the polyethylene film, as well as the slip of the material in the metal parts of the packaging devices.

Slip additives are made on the basis of fatty acid amides: oleomide (Slip O) and Erukomid (SLIP E).

Active substances of sliding additives allow us to ensure the execution of various functions. Adding amide of erukic acid is necessary in case after the package it is seal. Substances are activated on material for several days. The inclusion in the composition of the sliding additive with the amide of olive acid is relevant in situations where the lubricant is required regularly, it begins to operate on the surface during crystallization.

You can order a moving additive on our website, as well as managers by phone.

Drying additive (Dessicant)

The drying additive (dessicant) is an integral part of the production of products from the secondary polymer raw materials.

The main task that dehydrant is performed is the drainage of plastic materials, as well as the removal of excessive moisture from the surface of the product. Dessicant is capable of rid of moisture, even if it is inside the product and cannot be removed by other drying methods.

The undoubted advantages of the dehydrant is that it allows you to save electricity and prepare the recyclable for further production. Its application is relevant, if the dried equipment is unable to accommodate the entire amount of raw materials.

The use of a drying additive makes it possible to supply polymer raw materials, corresponding to the characteristics of purity and dryness, which will avoid marriage in production.

Order the additive from our managers by phone specified on the site.

Light stabilizer

The light stabilizer is a synthetic additive, extensively used in the manufacture of polymer products, which, by virtue of its operational purpose, are constantly exposed to ultraviolet and high temperatures.

A light-stabilizing additive allows you to slow down the aging process, fading and contributes to the preservation of physical and mechanical properties. Its main purpose to reduce the effect of ultraviolet on polymers molecules, thereby preserving the aesthetic appearance and operational condition of the product.

The additive includes spatially embarrassed amines that allow you to create high-molecular stabilizers that are not crystallizing on the surface of the product and non-washing out of its composition.

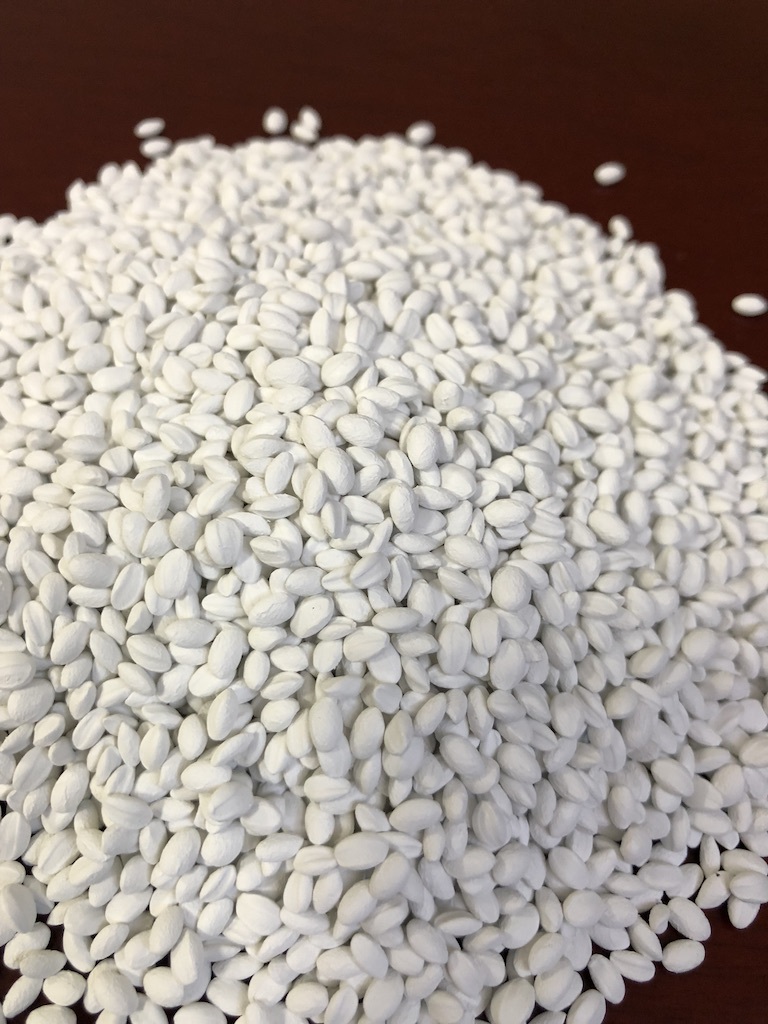

Antiblock

Anti-blocking additive found its use in the field of polymer film production.

The main task with which the polymer additive is successfully coping is the obstacle to the sticking of films in a roll or package due to the negative effects of high temperatures or pressure.

At the heart of the additive is silicon dioxide, which forms imperceptible roughness on the surface of the film, blocking the sticking of the material.

The anti-block crystallizes on the surface of the film, which makes it possible to push the film layers and save its operational characteristics.

The advantage of the additive is the smallest size of its particles that do not change the characteristics of the film, while maintaining its transparency.

You can order an anti-block additive on our website as well as managers

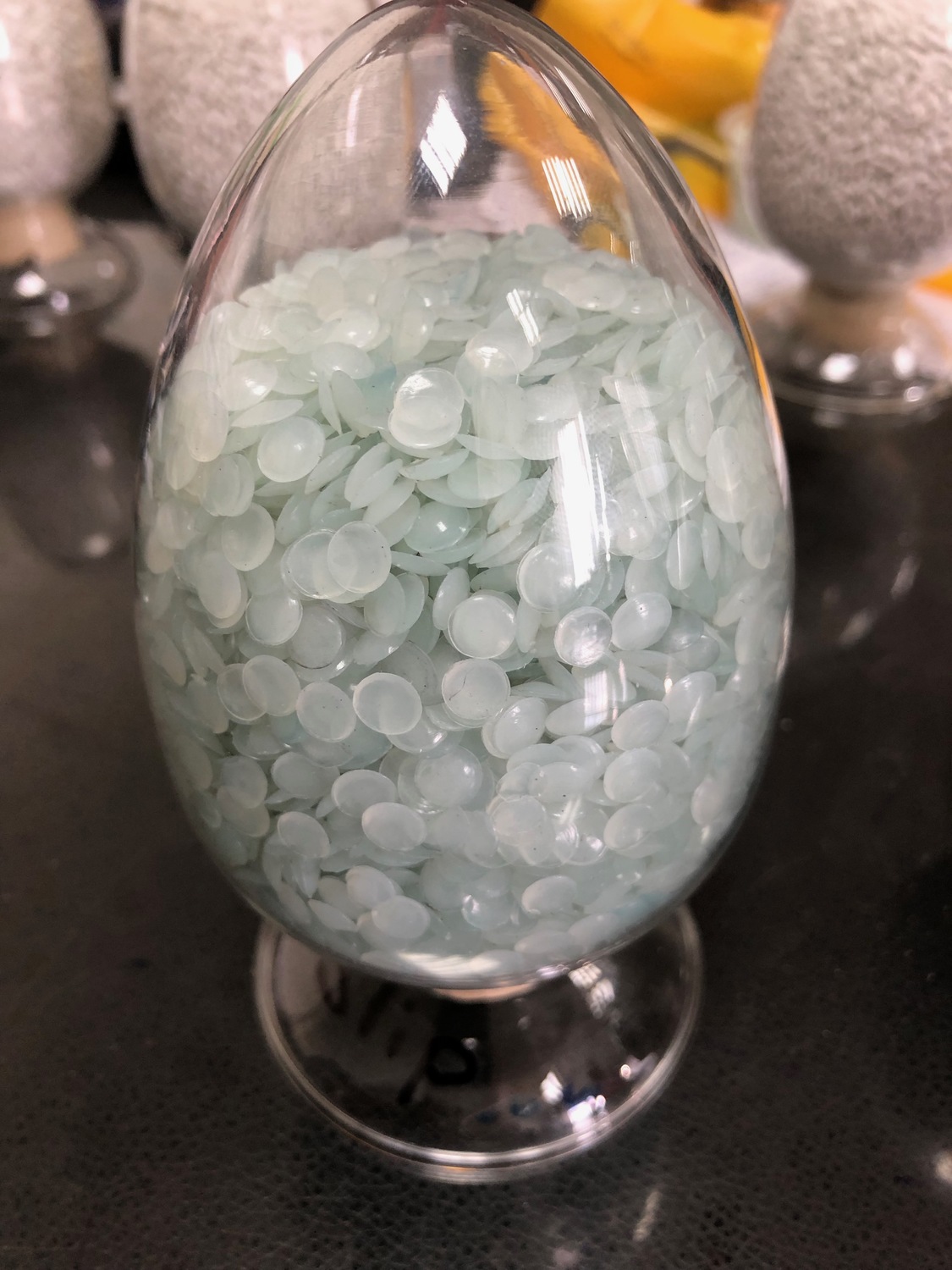

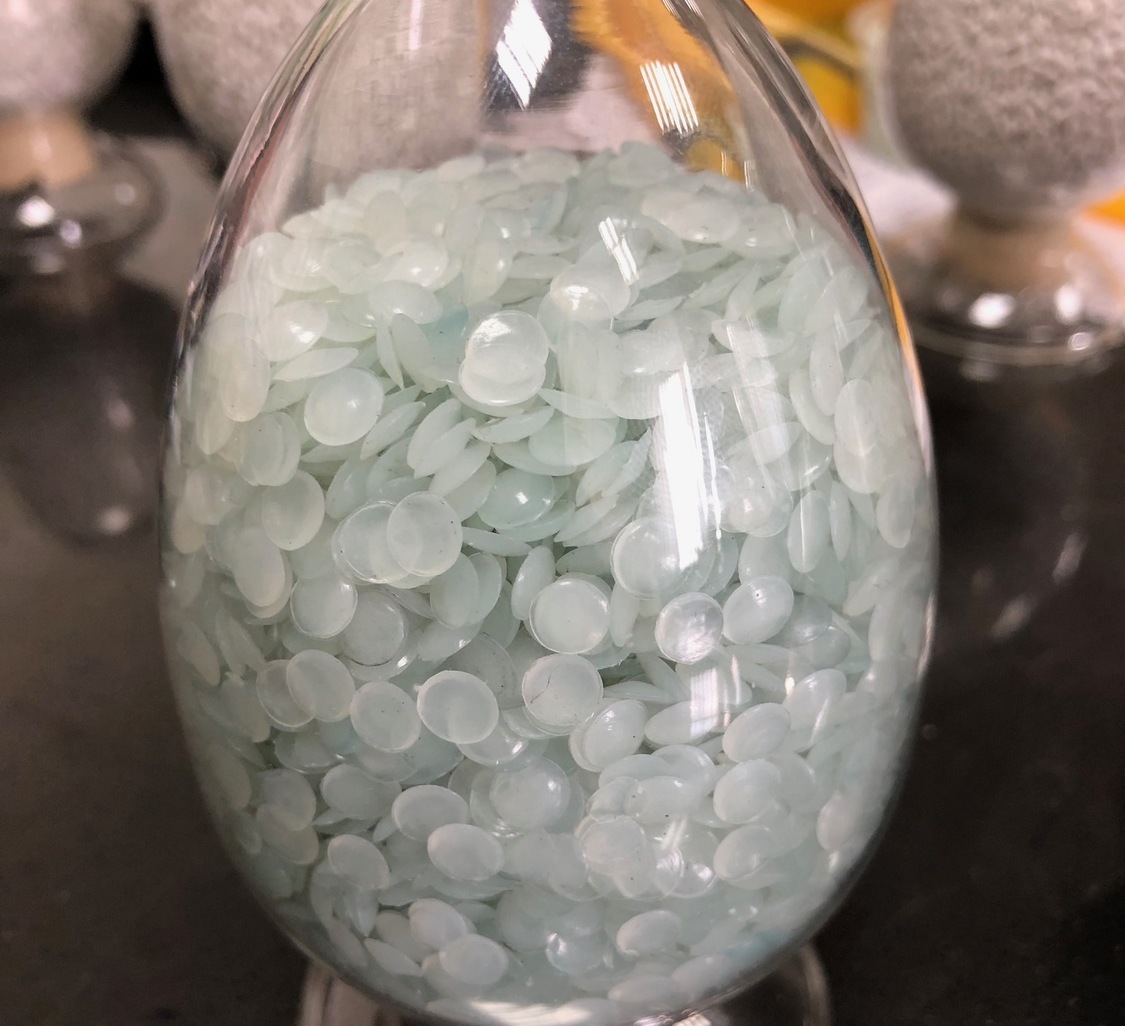

Processing additive

Processing additive - a synthetic compound used in order to process polymeric materials.

Its use provides the possibility of processing highly viscous substances, reduce the percentage of product defects and eliminate breaks for the melt of polymer materials.

The additive is most often used in the production of polyethylene films, extrusion of polymer pipes to prevent the formation of deposits.

The main advantages of applying additives are:

- improving the performance and efficiency of the equipment;

- lack of surface defects and faults;

- Reducing the processing temperature.

You can buy a processing additive by phone indicated on the site, as well as get advice from managers.

Sliding additive with anti-blocking agent

Combined antibrocing additive concentrate and sliding polyethylene-based additive.

Designed to reduce the ability to stick and reduce the force of friction and adhesion.

The input is recommended - 0.5-2%, depending on the desired coefficient of friction, film thickness.

Company DIME LTD

| Телефон | +7 (800) 222-79-20 |

| Адрес | Russia, Ryazan, pos. Murmino, Verhne-Sadovaya street, 1, 390528 |

| mb@pak-rz.ru |